BWA Series Spring Balancer

BWA Series :

| Capacity | Model No. | Travel | Weight |

| Kg. | Meter | Kg. | |

| 9.0 - 15.0 | BWA - 15 | 1.3 | 5.5 |

| 15.0 - 22.0 | BWA - 22 | 1.5 | 8.5 |

| 22.0 - 30.0 | BWA - 30 | 1.5 | 8.6 |

| 30.5 - 40.0 | BWA - 40 | 1.5 | 11.2 |

| 40.0 - 50.0 | BWA - 50 | 1.5 | 11.8 |

| 50.0 - 60.0 | BWA - 60 | 1.5 | 12.3 |

| 60.0 - 70.0 | BWA - 70 | 1.5 | 12.8 |

| Capacity | Model No. | Travel | Weight |

| Kg. | Meter | Kg. | |

| 9.0 - 15.0 | BWA - 15L | 2.3 | 8.5 |

| 15.0 - 22.0 | BWA - 22L | 2.3 | 8.6 |

| 22.0 - 30.0 | BWA - 30L | 2.3 | 8.7 |

| 30.0 - 40.0 | BWA - 40L | 2.3 | 11.4 |

| 40.0 - 50.0 | BWA - 50L | 2.3 | 12.0 |

| 50.0 - 60.0 | BWA - 60L | 2.3 | 12.5 |

| 60.0 - 70.0 | BWA - 70L | 2.3 | 13.0 |

EXISTING SAFETY FEATURES RETAINED

SAFETY PIN : Stops and locks drum pulley in the event of spring failure and thus prevents the fall of costly equipment and injury to the operator from falling load.

ADDITIONAL EYE : For fixing secondary support chain remains.

EXCLUSIVE SAFETY FEATURES INTRODUCED

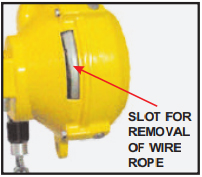

1.WIRE ROPE REPLACEMENT WITHOUT DISMANTLING

A small slot has been provided to facilitate removal and Re-installation of the wire rope without any

need for dismantling of the Spring Balancers. This will reduce the down time of the equipment. This

facility is not available for long range Spring Balancers.

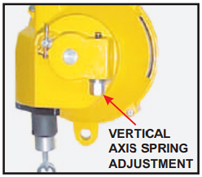

2.EASY ADJUSTMENT OF SPRING TENSION

In Spring Balancers from other manufactures the worm gear box for adjustment of Spring Tension worked in the horizontal axis. Gear box position has been rotated through 90 degrees so that spring tension adjustment can be made by working in vertical axis.

This will facilitate adjustment from ground level without any need to rise up to Spring Balancer hanging level. This reduces down time, facilities easy operation and reduces the chance of any mishap during an operator rising to the level of the balancer.

SAFETY FEATURES

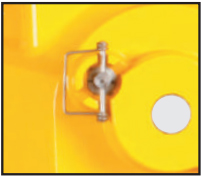

3.DRUM LOCK SYSTEM

Available to lock the spool while replacing a tool.

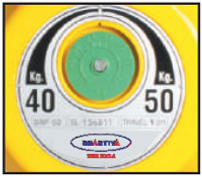

4.TENSION GAUGE

Lets operator see tension setting.

5.CONTAINERISED SPRING ASSEMBLY

No longer do you need to handle open springs which are difficult and dangerous to handle with sharp edges. All springs are now supplied in concealed containers for easy replacement. With containerised springs accidents are avoided during maintenance and replacements of springs.

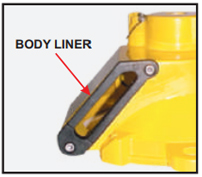

6.BODY LINER

In order to prevent wear of the slot of the Spring Balancer body, a split type Nylon liner for wire rope has been introduced in the new design Spring Balancers.

This liner can be removed and installed on site without any need for dismantling of the wire rope.

This will prevent wear of the costly body resulting in overall saving and reduced down time of

equipment.

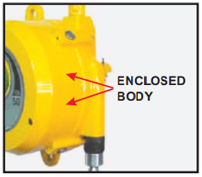

7.ENCLOSED BODY

Spring Balancers from other suppliers are supplied with opening both in Body and Cover causing accidental crunch of operator's fingers between revolving drum and the body of the Spring Balancers.To prevent this, side windows on the body and cover have been eliminated. This would prevent industrial accidents.

8.WIRE ARREST MECHANISM (BWA SERIES)

In the unfortunate event of accidental dislodging of the suspended weight, breakage of bottom hook / wire rope, spring tension will pull back the wire rope, resulting in whipping action likely to hurt personnel around.

This mechanism will lock the last revolving drum pulley and the wire rope assembly will be stopped with max. 20cm travel.

This will prevent the whipping of wire rope assembly and avoided any injury to operator or any personnel around