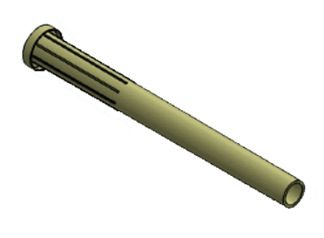

Plastic Tube Inserts

SHINGARE make Nylon Tube inserts are popularly used in industry to provide protection for tube ends of heat exchangers mainly (Shell and Tube type heat exchanger). The End of shell and tube type heat exchanger is mainly subject to erosion, corrosion, and impingement. Such corrosion is quick and substantial in marine industries due to use of salt water.

The Main Troubles Taking Place In Shell & Tube Heat Exchanger Are Briefly Described Below:

» Joint Testings Gun weighs less than 1.5 kg

» Simple, Quick and Reliable tube and joint testing. Test 7 to 8 tubes or 10 tube joints per minute.

» Interchangeable seal sets : Allows testing of tubes from 7.75mm to 30.63mm ID with easy to replace accessory.

» Air supply : Uses standard plant air supplies from 70 psi to 100psi (4.7 to 6.8 bar).

» Silent during use. Ergonomic design makes testing effortless.

» Each Kit is packed in an easy to carry case.

Shingare Industries PVT. LTD. Pvt Ltd has emerged out with the most effective solution for all the above troubles. We have introduced most cost-effective tube repair solution and that is known as SHINGARE make Tube Inserts. Also known as Ferrules or tube end Shield/Seal or Tube End Protector.

Material of construction (MOC)

Plastics: Nylon (Polyamide), LDPE (Low-density polyethylene), PP (Polypropylene).

Shingare Industries PVT. LTD. Pvt Ltd provide two types of insert head design. These are as follows :

BONNET TYPE : Generally Tubes are projected for about 3 mm to 5 mm outside the Tube Sheet of Heat exchanger. Bonnet head is used to cover such ends. This encapsulates the projection in such a way that the high velocity impingement has no effect on the tube mouth end. And provides longevity of tube mouth end. FLARED HEAD : When Tubes are not projected outside Flared head inserts are used.

Material Selection :

Plastic Tube Inserts : Suitable for Surface Condensers (Low temp range)

Nylon Tube Inserts : Suitable for temperature up to 150 degree Celsius.

PTFE Tube Inserts : Suitable for temperature up to 250 degree Celsius.

Tube Inserts prevent tube end erosion and costly retubing of Condensers and Heat Exchangers. PLASTIC TUBE INSERTS offer permanent protection for new tubes or extended life for old tubes already pitted or thinned at the insert section.

Some sizes also available in 4" lengths. Inquire about additional sizes.

| Part Number | Tube O.D |

Tube Gauge |

Tube Wall Thickness |

Tube I.D |

Insert Length |

| STIN-58186 | 5/8" | 18 | 0.049 | 0.527 | 6" |

| STIN-58206 | 5/8" | 20 | 0.035 | 0.555 | 6" |

| STIN-34166 | 3/4" | 16 | 0.065 | 0.620 | 6" |

| STIN-34186 | 3/4" | 18 | 0.049 | 0.652 | 6" |

| STIN-78166 | 7/8" | 16 | 0.065 | 0.745 | 6" |

| STIN-78186 | 7/8" | 18 | 0.049 | 0.777 | 6" |

| STIN-78196 | 7/8" | 19 | 0.042 | 0.008 | 6" |

| STIN-1166 | 1" | 16 | 0.065 | 0.870 | 6" |

| STIN-1186 | 1" | 18 | 0.049 | 0.902 | 6" |

| STIN-1206 | 1" | 20 | 0.035 | 0.930 | 6" |

METAL TUBE INSERTS

In order to provide protection to the tube mouth ends of shell and tube heat exchanger tube inserts are used. These tube inserts are generally in the form of metal, plastic or polymer. As the name suggests tube inserts are inserted into ends of tubes thus provides protection to the ends. maintaining is always cheaper then replacing. Since it ensures cost saving as well as time saving. All tube failures happen at the few inches from tube inlet end. As a solution we can use thin wall covering in form of metal tube inserts which expands full length into the inlet end of condensers and heat exchanger. Bhartiya make heat exchanger tube inserts are specially designed make sure a smooth and gentle transition of the fluid down the tube inserts to the condenser or heat exchanger tube, We have below ferrous and non ferrous tube inserts.

FERROUS :

Inconel alloy inserts are typically used of high temperature applications. They are wrapped with ceramic paper. In this one end of insert is flared and the other end is a reverse tapered to hold the ceramic fiber properly.

NON FERROUS :

Non Ferrous inserts are used in application with very high temperature such as 900 degree Celsius. It is suitable when such high temperature present on tube side of the heat exchanger. At this temperature tube sheet can't be wrap, instead of this we can use tube inserts. The tube insert has an hour glass form. This creates an air gap between the tube insert and the parent tube. This gap can be wrapped with high temperature 1260 degree Celsius ceramic paper. The paper is taped in place. We recommend tape full length. There are two advantages for full length tape, one, more high temperature ceramic paper can be compressed on to the tube insert, two, the tape protects the ceramic paper which cannot withstand even minor abuse. Some tube inserts have anchors that become imbedded into the refractory others have pins with ceramic paper to set the tube insert at a specific height from the tube sheet.